RFID/NFC lab measurements

With modern measuring equipment, a measuring chamber and the option of taking measurements in a working environment, nothing stands in the way of your project's success.

RFID/NFC tags from smart-TEC are developed and produced tailored to your requirements. Shape, color, size, imprint, material, attachment as well as thermal, chemical and mechanical resistance are factors that play a major role in the development. Another key point is the technical and physical measurements carried out in our laboratories as part of the quality control process.

The range of electrotechnical and physical parameters and influencing factors that need to be taken into account for successful project implementation is very extensive. That's why we support you with numerous tests, measurements, evaluations and documentation in our in-house measurement laboratories to ensure the success of your project.

We offer the following measurements:

HF (13.56 MHz) & UHF band (868 and 915 MHz)

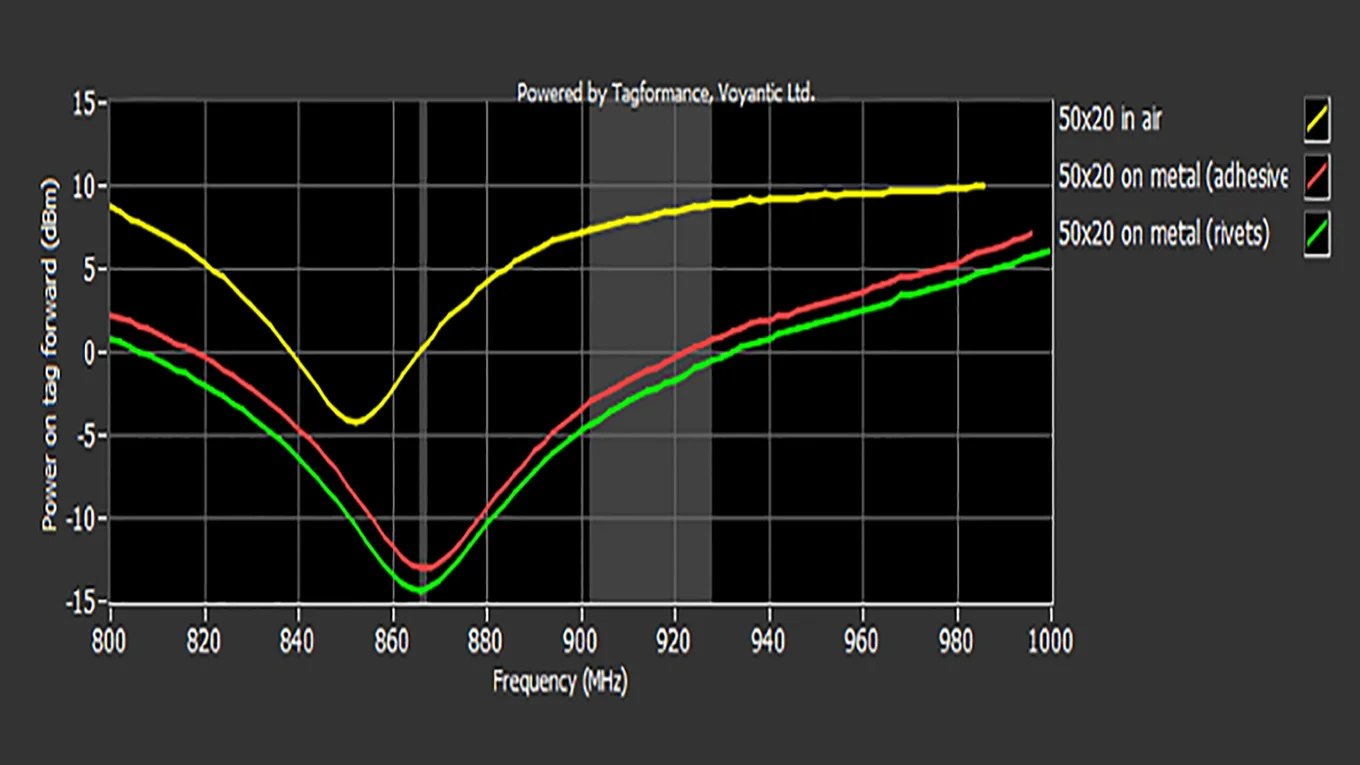

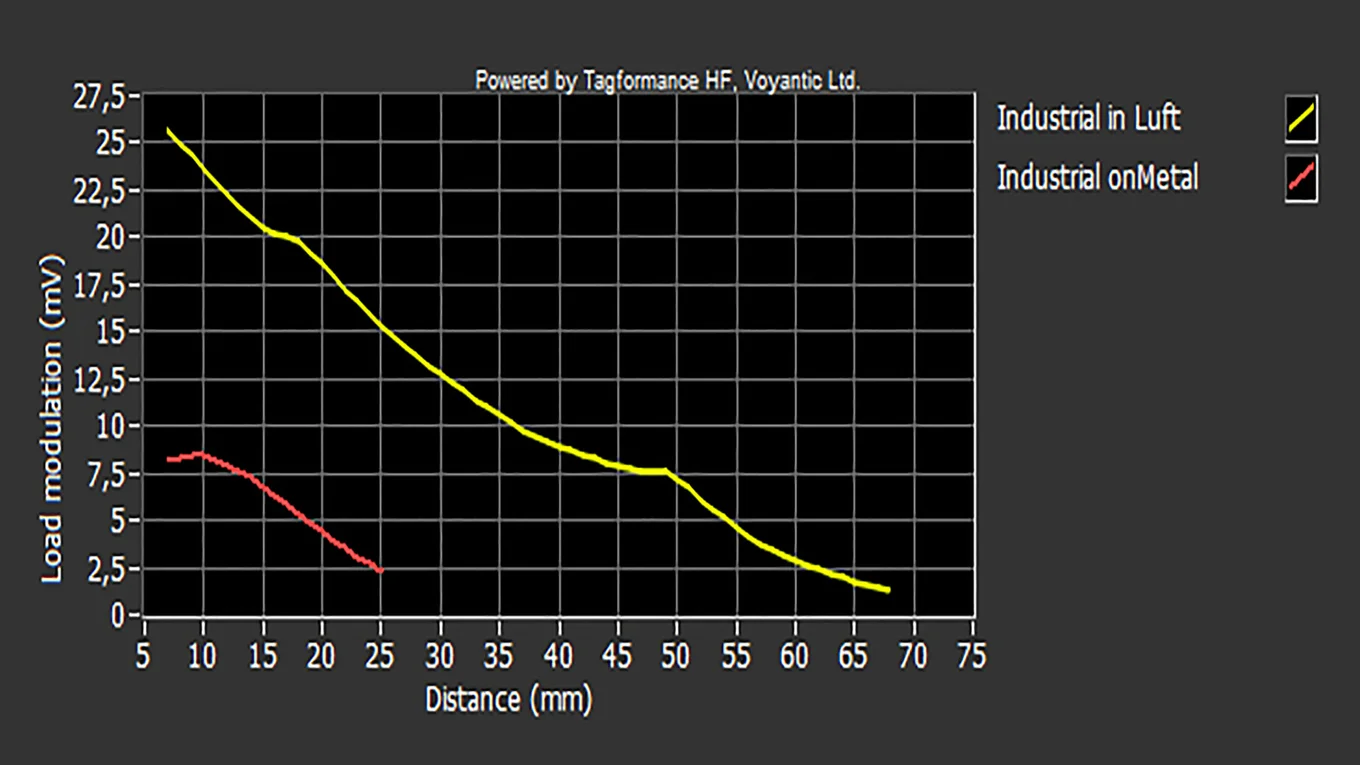

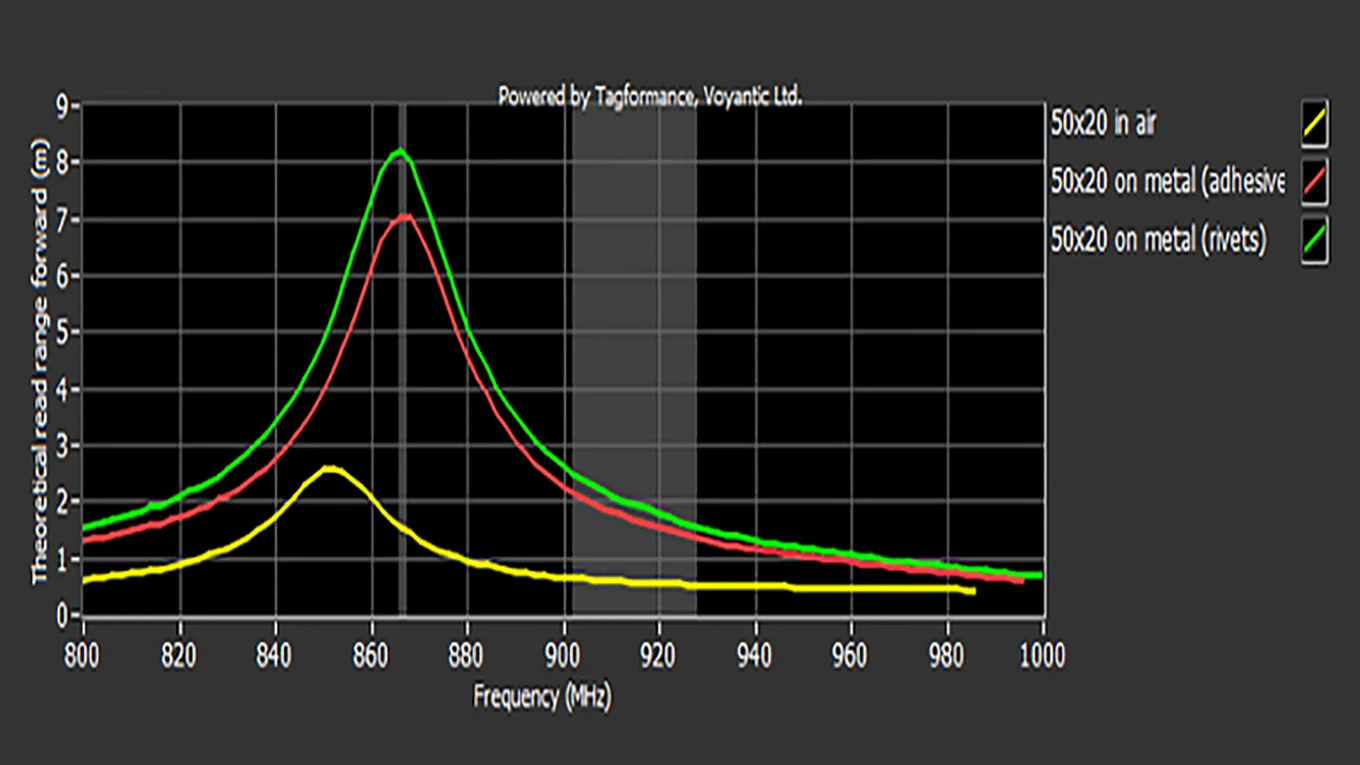

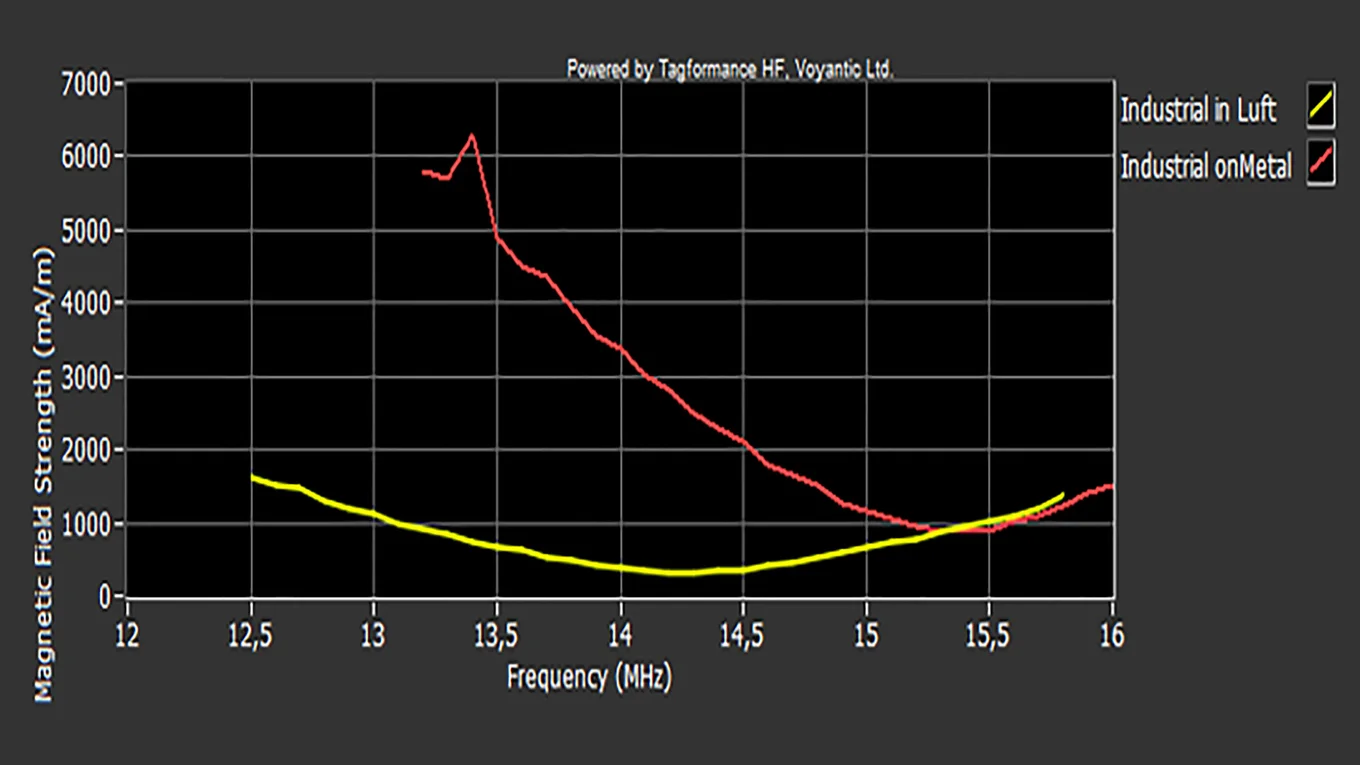

In order to define a parameter for the performance of RFID/NFC tags that is independent of the reader, the required response field strength (referred to here as sensitivity) is determined. With the knowledge of the required response field strength, the suitability of an RFID/NFC tag can be simulated in a wide range of environmental conditions.

We can simulate the possible read and write range of RFID/NFC tags, taking into account different application scenarios, surfaces and materials. With the help of the resonance curve we measure, we can determine the most suitable RFID/NFC tags for the individual application.

As the RFID/NFC tags are rarely ideally aligned with the reading antenna when they are detected, the ratio of the reading range to the angle of incidence of the EM radiation is important. Accordingly, simple conclusions can be drawn about the reading behavior, even with moving RFID/NFC tags. With our measurement capabilities, we determine the radiation behavior of the RFID/NFC tags and can thus determine suitable RFID/NFC tags for the application.

We also offer you the option of on-site measurements. This allows you to ensure that the frequency, size of the RFID/NFC tag and the read/write devices are optimally matched to your intended use, your environmental conditions, the products to be tagged and any mechanical, thermal and chemical stresses.

Our possibilities in the laboratory

The range of electrotechnical and physical parameters and influencing factors that need to be taken into account for successful project implementation is very extensive. This is why we support you with comprehensive tests, measurements, evaluations and documentation in our in-house measurement laboratories to ensure the success of your project.

We carry out tests and coding in the HF, NFC and UHF frequency ranges in our in-house measurement laboratories.

RFID/NFC read/write devices

The selection of RFID/NFC read/write devices is large. There are specialized RFID/NFC read/write devices for all types of applications.

From mobile RFID/NFC handheld readers powered by rechargeable batteries to stationary RFID/NFC readers and mobile devices such as smartphones or tablets.

These are some of the parameters that influence the selection of RFID/NFC read/write devices:

- Desired system frequency

- Required performance/range

- Application area and ambient conditions

- Integration into existing IT systems

- and much more

Technical support

To ensure that your identification project is a complete success, we support you not only with sound project advice in advance, but also in all technical matters on site. Our RFID/NFC specialists analyze your area of application on site and inspect the existing IT environment.

We also advise you on frequency and chip selection, combine several functions to create an RFID/NFC multi-tag, consider mounting options and carry out tests with RFID/NFC readers in our own production and development laboratories.

Individual development of RFID/NFC transponders

Special requirements, use cases, environmental conditions and areas of application form the basis of our customized product development.

We not only have state-of-the-art testing and inspection systems at our disposal, but also the 75 years of experience of the entire RATHGEBER Group.

Customized RFID/NFC transponders are optimized in terms of frequency, chip technology, shape, color, size, imprint, type of attachment, material, necessary thermal, mechanical and chemical resistance.

Further information on individual product developments can be found here.