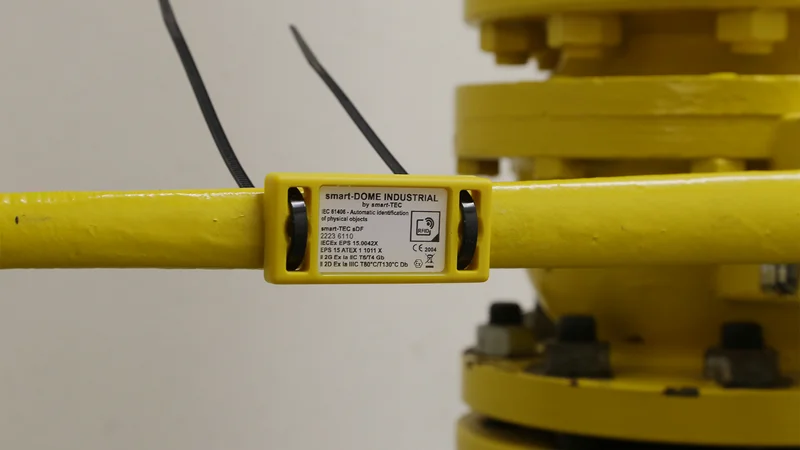

Ex-protection-certified RFID transponders for industry

27.11.2025

Oberhaching, November 2025

RFID technology has established itself in a wide range of industries as a secure and durable way of marking machines, tools and materials. However, as soon as components are used in hazardous areas, the safety requirements for the RFID transponders used increase.

smart-TEC, a specialist in industrial RFID identification solutions, had the relevance of explosion protection (explosion protection) for RFID transponders with PU encapsulation tested and certified many years ago.

The focus was on two sources of danger that can occur with fully encapsulated RFID transponders, despite their passive functional principle: heating of the RFID chip and electrostatic charging of the polyurethane encapsulation.

Heating of the RFID chip - an underestimated source of energy

Passive RFID transponders consist of semiconductors and antenna structures that are supplied with energy by the reader's electromagnetic field during reading. This results in a slight but measurable heating of the chip. In hazardous areas, however, even a local increase in temperature can be sufficient to ignite gas or dust atmospheres. For this reason, RFID transponders that are to be used in potentially explosive areas must demonstrate the following points as part of the certification process:

- the maximum surface temperature is clearly defined and tested

- there must be no hotspots due to the energy absorption in the electromagnetic field

- the PU encapsulation enables safe heat dissipation

Without these verifications, even a passive RFID industrial transponder can become a potential ignition source.

Electrostatic charging - risk due to PU potting

Plastics such as polyurethane have excellent protective and insulating properties. However, friction, movement or cleaning processes can lead to electrostatic charging.

If a discharge occurs, there is a risk of sparking - and thus a possible ignition of the surrounding atmosphere. For this reason, the electrostatic effect of RFID transponders with PU encapsulation must be comprehensively tested and evaluated as part of the Ex certification process.

Explosion protection for RFID transponders is much more than a formal process. Both the heating of the semiconductor chip and the electrostatic charging of the PU encapsulation are ignition sources that must be actively prevented.

smart-TEC ensures that our industrial RFID transponders can be used in Ex zones without hesitation thanks to careful and conscientious ATEX/IECEx and UKEx certification.

In addition to our RFID transponders, we have also had our production in Mindelheim (Allgäu) certified for explosion protection. This enables us to ensure explosion-proof production from goods receipt to delivery to our customers.