RFID technology

What is RFID

RFID (Radio Frequency Identification) is the contactless exchange of data between an RFID tag and an RFID reader/writer. For data transmission, the RFID read/write device creates a magnetic or electromagnetic field that supplies the passive RFID transponder with energy. As long as the RFID tag is in the electromagnetic field of the RFID reader/writer, it is supplied with energy and data can be exchanged. Information can be read from the chip of the RFID tag, but new data can also be stored on the chip.

Do you have any questions? We will be happy to help you:

RFID tags can be offered in almost all shapes, materials, sizes and colors. The specific structure depends on the application. Inside, every RFID tag consists of at least a microchip and a printed, laid or etched antenna. The chip and the antenna (also known as the inlay) are very sensitive and can therefore only withstand limited mechanical, thermal or chemical stress. Application-specific "packaging" of these electronic components is therefore necessary. The simplest form is packaging as an RFID label. This is sufficient for many applications - however, with this form of packaging, the chip is only protected by a simple film or a layer of paper.

If it needs to be a little more stable or robust, packaging the RFID electronics in a laminated card is recommended. If this is not enough, especially in an industrial environment, the sensitive inlay (=chip + antenna) should be encapsulated in a plastic housing. This is the most robust, durable and insensitive form of packaging.

The "single chip" RFID tag consists of a substrate with an antenna and chip, known as an inlay for short. A tag system consists of the RFID tag, a reader, the software and the application process including service.

The memory size of the chip depends on the application. Commercially available memory sizes are between 4 bytes and 8 kbytes. In the simplest case, usually in electronic article surveillance, even 1-bit memory can be used. To illustrate this, a 4 byte memory can only store one unique number (Unique ID=UID), whereas an 8 kByte memory can store 4 typewritten pages consisting of 30 lines of 60 characters each. In addition to simple storage, there are a number of other chip functionalities such as write protection, PIN authorizations, encryption of data content, cryptographic functionalities and many more. The individual specifications depend on the application and the required security level.

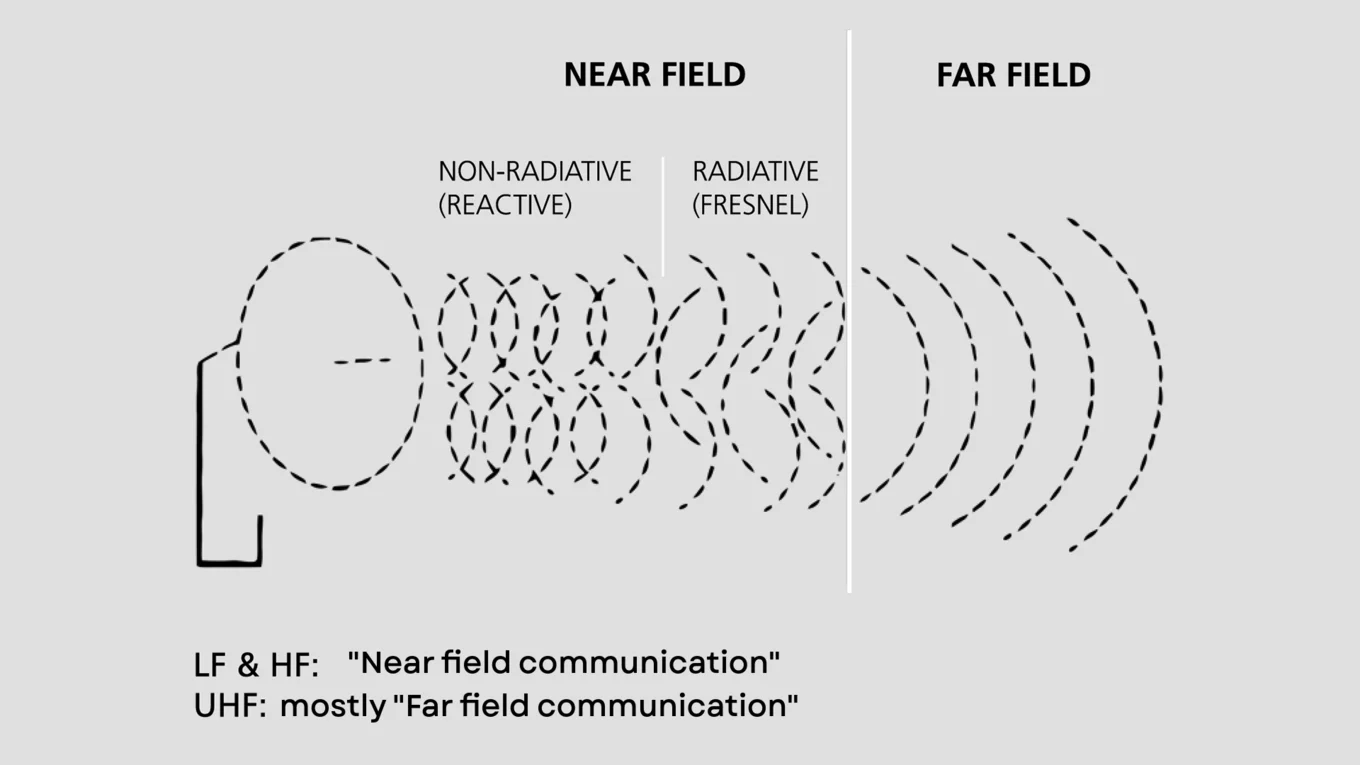

Principle of inductive coupling for LF and HF RFID transponders:

The transmitter emits an electromagnetic field via the antenna coil, which is picked up by the RFID tag. A current is then induced in the transponder coil by means of induction. This current provides the energy with which the RFID tag is operated. By selectively attenuating the current over time via circuits in the chip, a separate signal can be generated. This change in the field is registered by the transmitter and is used for digital communication.

Principle of "EM backscatter" for UHF RFID transponders:

The transmitter emits an electromagnetic field via the antennas, which is picked up by the RFID tag. The electromagnetic field induces a current in the tag antenna. This current provides the energy with which the RFID tag is operated. The RFID tag modulates the carrier signal, which is then received by the transmitter for communication

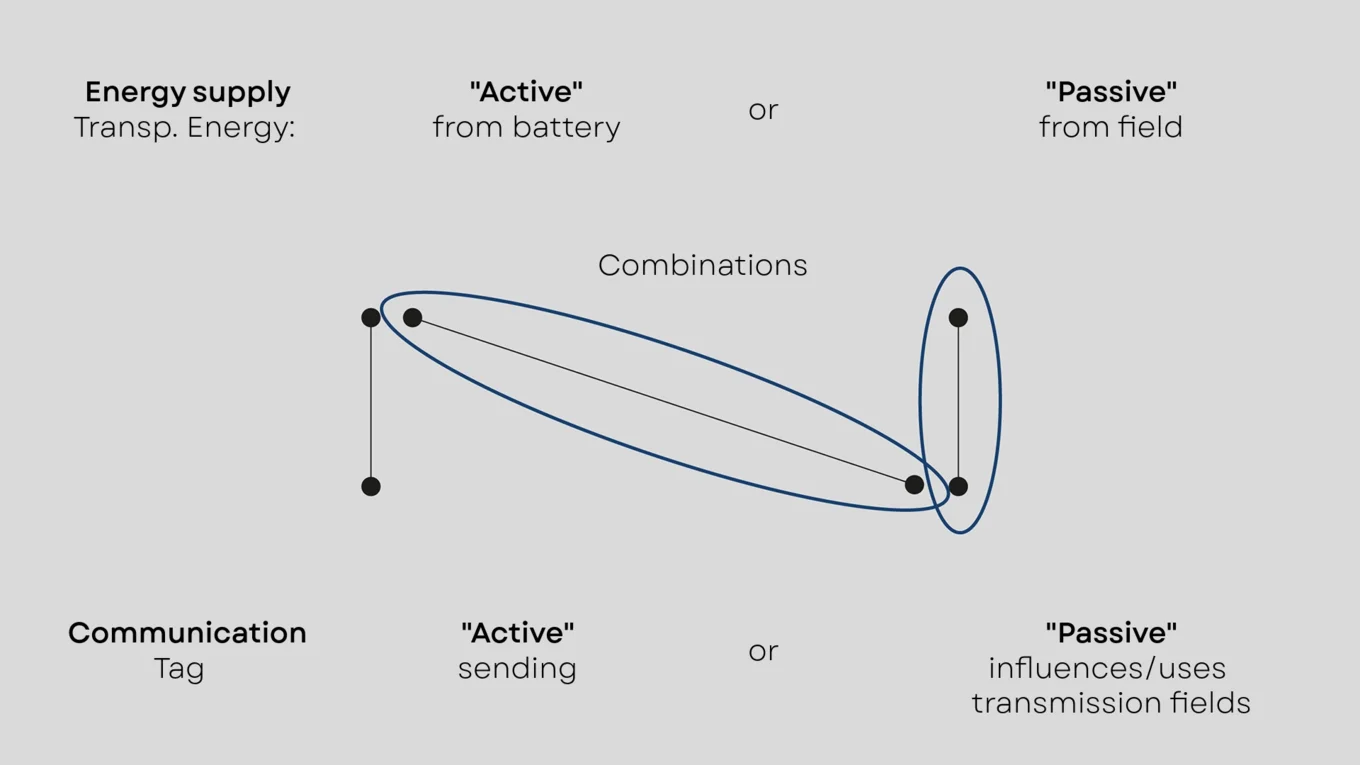

There are two basic types of RFID tags - active and passive. Active RFID tags have their own power supply, e.g. an integrated battery, and can transmit data over a greater distance (up to 100 m). Passive RFID tags draw their energy for data transmission solely from the electromagnetic field of the RFID read/write device.

As an intermediate type, there are also semi-active or semi-passive RFID tags, which have their own power source but do not fully function as their own transmitter. The RFID tag is powered by a battery, no power has to be drawn from the electromagnetic field, but the response is generated via the modulation of the field, which means that the field is not amplified again.

1. read-only: Read-only tags can be individually written to once by the manufacturer, but it is not possible to add, delete or overwrite information at a later date.

2. Write-Once, Read Many (WORM): WORM tags can only be written to once by the customer. After that, they can only be read, but not written to again.

3. read and write: Read and write tags allow unlimited writing and changes to the memory content. By setting a write protection, these RFID tags can also be blocked for both reading and writing from a desired point.

There are three frequency ranges in which RFID systems are categorized:

Low Frequency (LF = 125kHz)

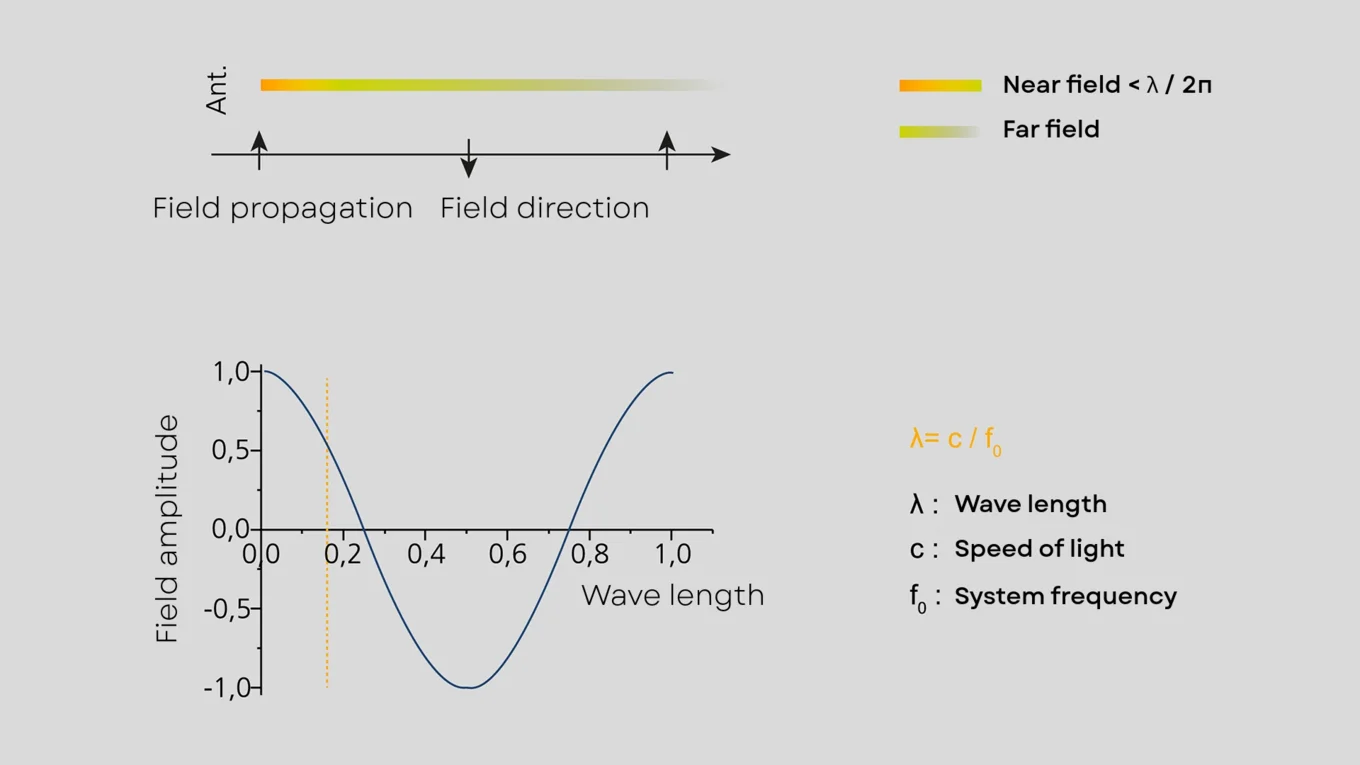

This freely accessible frequency range is characterized by low transmission rates and distances. These systems are usually inexpensive and easy to set up, and do not require registration or fees. The RFID tags make use of the near field of electromagnetic waves and are passively supplied with energy through inductive coupling. One advantage is that the RFID tags in this frequency range are relatively insensitive to metal and liquids, which means they can be used in animal identification, for example.

High Frequency (HF 13.56 MHz)

The HF frequency can be used universally and is characterized by high transmission rates and high clock frequencies. RFID tags operate on the HF 13.56 MHz frequency - a short wavelength for which only a few antenna turns are required. This means that the RFID tag antennas can be smaller and simpler. It is possible to use etched or printed antennas. This means that the inlays (=chip + antenna) can be produced as continuous foils, which considerably simplifies further processing towards large quantities in a roll-to-roll process

Ultra High Frequency (UHF 860 - 950 MHz divided into sub-bands)

These systems have very high transmission speeds and ranges. Due to the shorter wavelengths, a dipole is sufficient as an antenna instead of a coil, the field propagation is sufficient for beam optics, which enables directional propagation. UHF tags are also predominantly produced as a single layer of foil, which facilitates processing in large quantities in a roll-to-roll process. The use of a back-up battery for the energy supply (semi-passive tag) makes sense in some applications due to the already long ranges in order to extend the range even further. In this context, it must also be mentioned that certain frequency ranges in the microwave range have not yet been developed cost-effectively and may also be subject to local licensing restrictions. For example, the FCC UHF frequency range around 915 MHz is not yet approved in Europe. Discussions are currently underway to make part of the frequency range usable for RFID. THE ETSI UHF frequency range around 868 MHz will remain available for RFID.

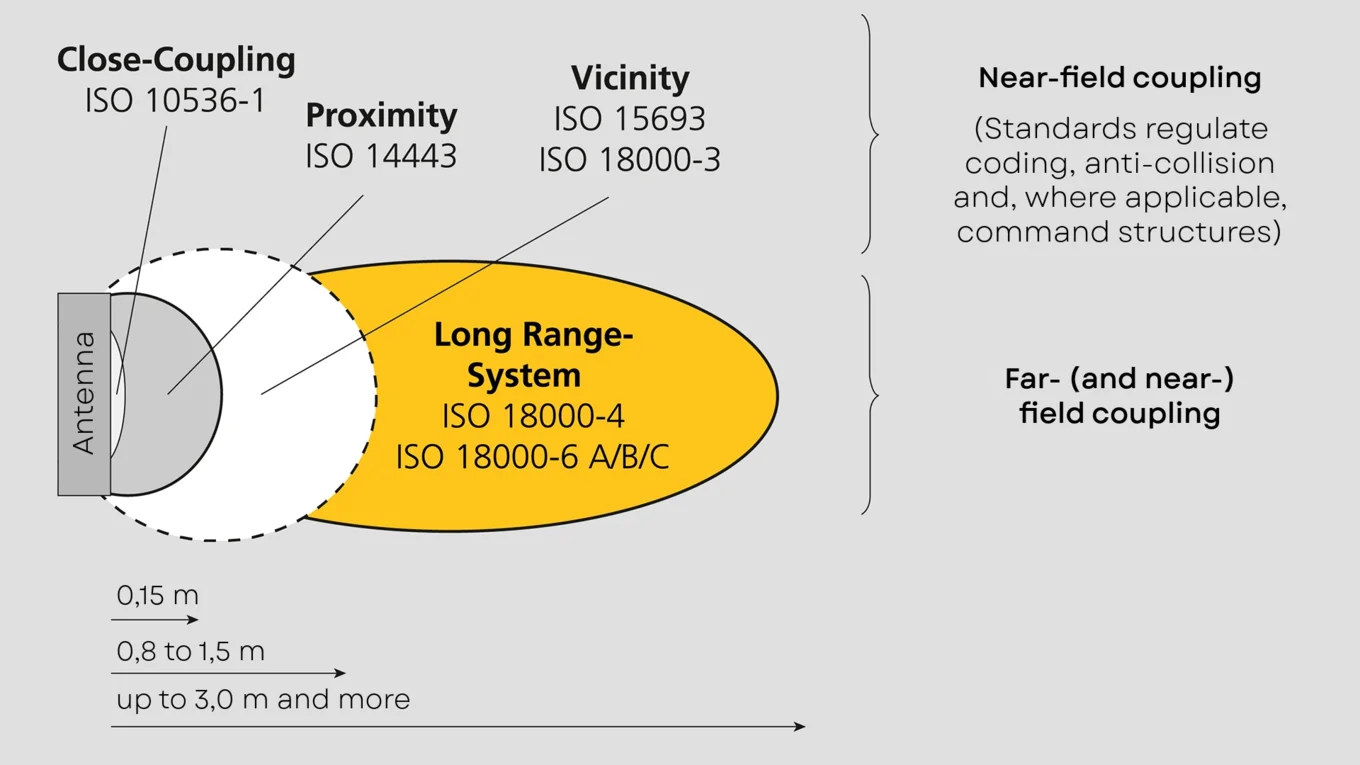

Close coupling

Frequency range: 1 Hz - 30 MHz

Range ranges: 0 - 1 cm

The RFID tags must be inserted into a reader or their position must be precisely defined during reading. Due to the close coupling, larger amounts of energy can be provided to the RFID tag, whereby it should be noted that the transmitted energy increases proportionally to the frequency. Data transmission between the RFID tag and RFID reader can take place via inductive or capacitive coupling. Applications that require maximum security are implemented using this method.

Remote coupling

Frequency range: between 100 and 135 kHz, 6.75 MHz, 13.56 MHz and 27.125 MHz

Range: up to 1 meter

Data transmission is achieved by inductive coupling in all remote systems. The energy transmitted from the reader's magnetic field is sufficient to operate the chip, as the RFID tag is powered passively

Long range

Frequency range: microwave range

Range ranges: 1 m - up to 10 m

Data is transmitted using the backscatter method, but the energy transmission is only sufficient for sending a wake-up or sleep signal. A back-up battery is required to supply the RFID tag chip with energy and to maintain the stored data. Toll systems would be a conceivable area of application.

Your advantages

- Each chip has a unique serial number (UID or TID) that is only assigned once worldwide. This guarantees unique assignability at individual product level and complete product individualization

- Rewritable data memory in the chip and therefore flexible data management directly on the product. The information on the RFID data carrier can be changed, deleted or added to at any time. Product, maintenance, production or service data is available directly on the product

- Visual contactless communication between the RFID tag and the read/write system offers insensitivity to soiling thanks to attachment in protected areas, invisible integration into existing products and simplified process optimization

- The high speed of communication is equivalent to a 100% first read rate for barcodes

- The simultaneous reading of several RFID tags in one work step (bulk reading) accelerates processes